德國soudokay SK A45-G氣體保護(hù)藥芯焊絲

SK A45-G high alloyed steels

Classifications gas shielded bl cored wire

DIN 8555

MF 10-GF-65-GT

Characteristics

Chromium-Niobium-Molybdenum alloy with addition of Tungsten and Vanadium designed to

resist high stress grinding abrasion with low impact and solid erosion at service temperatures

up to 650 °C. The deposits will readily show stress relief cracks.

Microstructure: Austenitic matrix with hexagonal primary and eutectic carbides

and nodular Nb carbides with complex combined carbides

Machinability: Grinding only

Oxy-acetylene cutting: Cannot be flame cut

Deposit thickness: 8 to 12 mm in 2 or 3 layers

Shielding gas: Argon + 2 % Oxygen

Field of use

Wear plates, sinter finger crushers, exhaust fan blades in pellet plants, perlite crushers,

bucket teeth and lips on bucketwheel excavators, boiler fan blades, burden area in blast

furnace bells, etc.

Typical analysis in %

C Mn Si Cr Mo Nb W V Fe

5,3 0,1 0,7 21,0 6,3 6,0 1,8 0,75 balance

Typical mechanical properties

Hardness as welded: 63 HRC

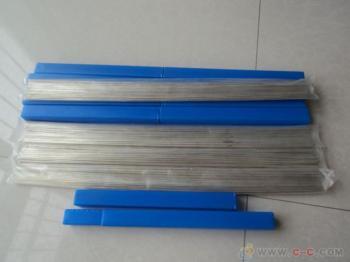

Form of delivery and recommended welding beters

Wire diameter (mm) Amperage Voltage Stick-Out

1,6 180 – 200 26 – 30 20 max.